Useful synergy effects in collaboration with Hälg & Co. AG – building technology

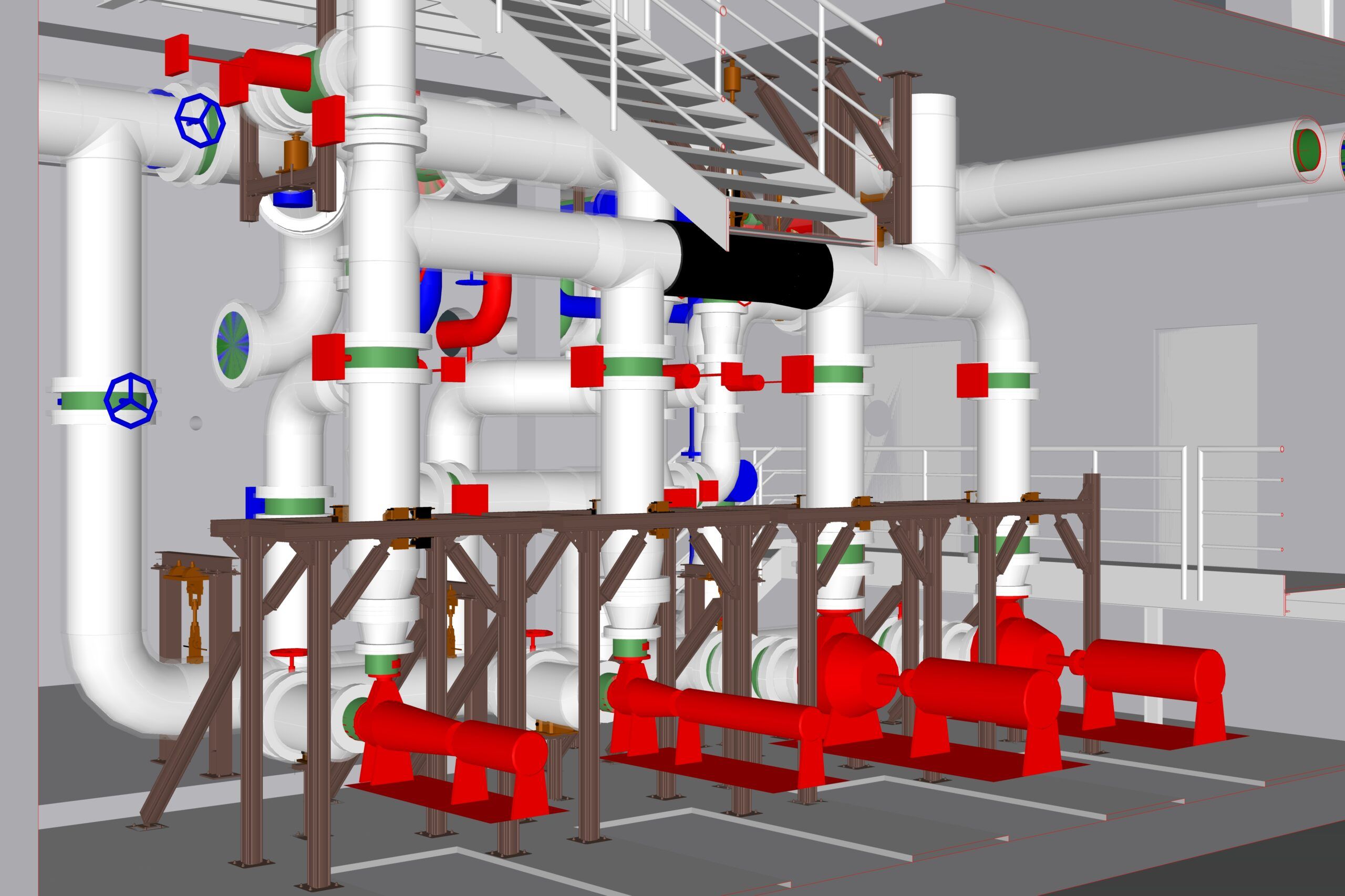

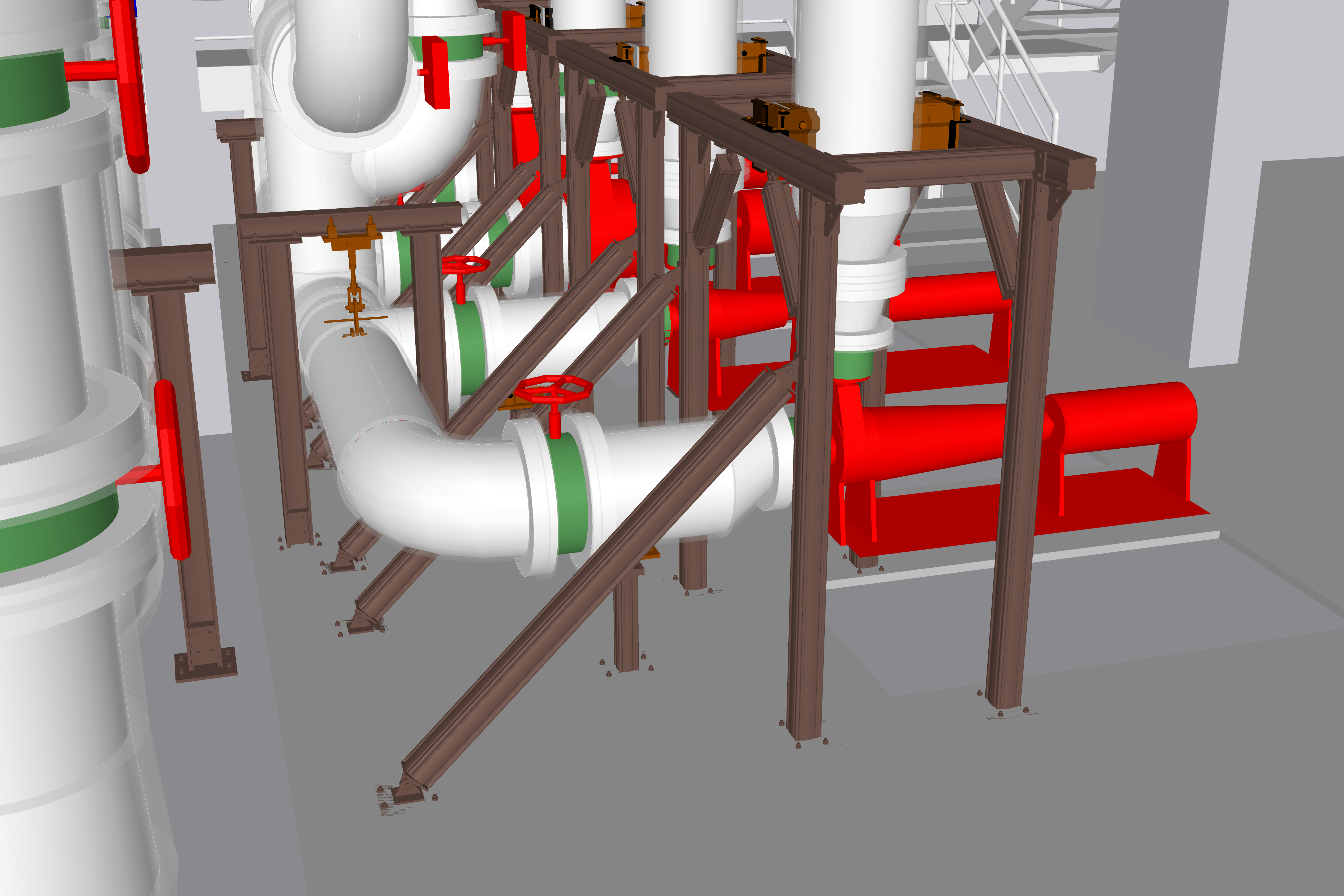

In their new district heating centre, the public works department of St. Gallen were confronted with approx. 300 m of water-bearing pipelines – mainly thick – walled carbon large bore piping up to a nominal size of DN 400 – and operating at a pressure of up to 16 barg and a temperature of 180 °C. In stand-by mode, part of the plant is always maintained at operating temperature. This leads to great temperature differences and hence to differences in movements between parts of the plant that are cooling and those maintained at the operating temperature. Hälg & Co. AG supplied the complete package of pipelines, supporting structure, pumps and fittings. On the basis of positive collaboration in the past, Hälg & Co. AG awarded the contract for the static calculations of the piping to SI-TEC, and during the course of the project the planning of structural supports as well. As a result, all those involved were able to benefit from the synergy effects produced by the single-source planning.

Success from a combined effort: at the end of the day, the district heating system of the public works department benefited from the many years of cooperation and mutual support in expertise and areas of competence. SI-TEC was therefore also able to master the challenge of managing the differences in movement between parts of the system with temperature differences in the stand-by load case.

Our services and core activities

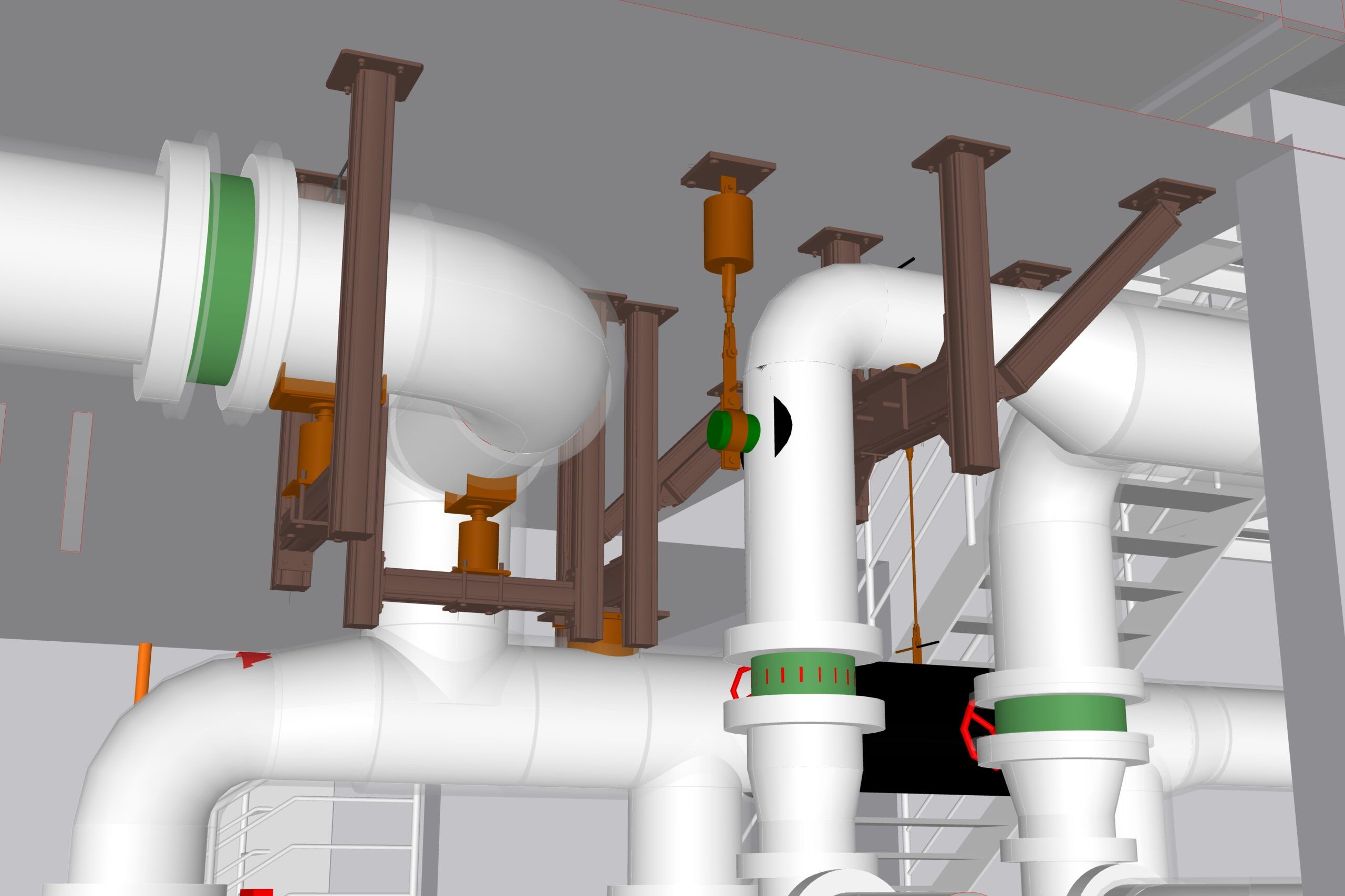

The core tasks of SI-TEC comprised stress calculation for the pipelines by means of Rohr2 and the planning of structural supports for pipelines from the Sikla product range with Aveva E3D. In particular, the greatest challenge was to master the differences in movements between subsystems with temperature differences in the stand-by load case. Added to this were large thermal displacements of very heavy pipelines (due to their water content) and large support reactions in combination with sensitive pump nozzles. It was only possible to master these conditions by using various compensators and spring/constant hangers.

»The pipeline system of the Lukasmühle district heating centre presented a number of technical challenges: large nominal sizes, high operating temperatures, compact pump layout, large thermal differences in movement while the plant is in stand-by, sensitive equipment nozzles, etc. In SI-TEC we found precisely the right partner for the static calculations of the pipeline and the planning of structural supports: they provided specialist knowledge in the field of statics along with expertise in 3D layout planning, while also being fast and communicative. Through their contribution, the employees of SI-TEC made an important contribution to our success in this project.«

GEOFFREY MOSER - Senior Project Manager Industry, Hälg & Co. AG

Customer benefits through SI-TEC

Collision-free layout, permissible nozzle loads – even when taking account of these constraints, we were able to fully solve all of these challenges in the customers’ interests with regard to costs and function. We explained the specifications of the required compensators and provided support in their purchase.

In addition, we supplied appropriate and proper installation drawings for the structural supports. This (along with the deployment of Sikla products) led to a considerable reduction in installation time. And we continue to be reliable, technical contacts in all matters concerning pipeline statics and the structural supports.